Climate Risk Management to Secure Business Operation of Chicken Farming and Improve Livelihoods

A first version of this blog has been published on the USAID APIK website, in Bahasa Indonesian. The original article was writtent by the original article is authored byHidayatullah Al Banjari, Private Sector Engagement Advisor – USAID APIK; Nyoman Prayoga, Communications Specialist: Knowledge Management and Reporting – USAID APIK; Stella Puteri, Communications Specialist: Media and Outreach – USAID APIK. Please note that the original article does not present the recent outcomes presented in this English version.

The impact of climate change on the egg industry

As one of the biggest egg production centers in Indonesia, Blitar District in East Java supplies 70% of the eggs for East Java and contributes to 30% of the national egg supply.[1] In 2018, the population of layer chickens in Blitar District was 15,365,100 chickens with a total egg production of 155,802 tons.[2] Most of the chicken farms are located within Srengat, Ponggok, Kademangan, Wonodadi, Kanigoro, and Udanawu Sub-districts.

In recent decades, the egg production is threatened by the impact of climate change and disasters. Extreme temperatures or frequent heavy rains lead to a decline in the egg production, a reduction of the egg quality, and also an increase in the risk of chicken and egg diseases (e.g. Egg Drop Syndrom). The fact that most of the chicken farms in Blitar District are located in areas prone to hydro-meteorological disasters (such as flood, landslide, and drought) increases the vulnerability of chicken farming businesses.

A decrease in egg production not only affects the livelihood of the chicken farmers themselves, but also other businesses in the poultry sector supply chain. For example, when production decreases, farmers have less income, which leads to reduced demand for chicken feed. With the huge number of chicken farmers in Blitar District (90% of them are smallholders with less than 10,000 chickens per farmer), this is a very important market for chicken feed companies.

Engaging private sector at national level to build smallholder chicken farmers resilience

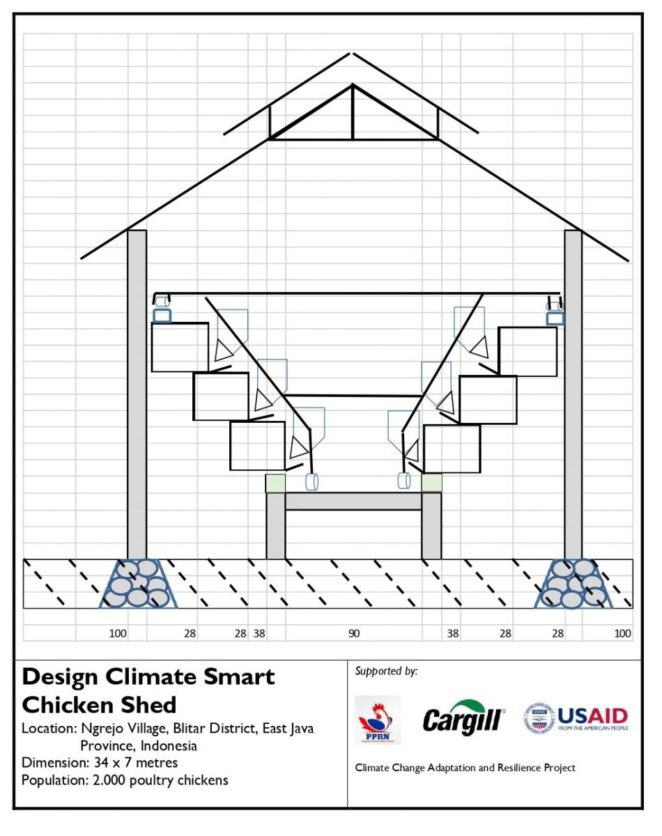

In order to tackle the issue, USAID Climate Change Adaptation and Resilience Project (Adaptasi Perubahan Iklim dan Ketangguhan – APIK) collaborated with PT Cargill Indonesia and National Smallholders Layer Farming Group (Paguyuban Peternak Rakyat Nasional) to improve chicken farmers’ resilience to climate and weather impact through training, awareness raising, and conducting a pilot project on a new design of climate-smart chicken sheds (see Fig.1). This smart chicken shed design allows better air circulation and more efficient water and food distribution that will help farmers deal with extreme weather conditions, will increase water and food efficiency, and improve the quality and quantity of eggs.

The pilot climate smart chicken shed carries a number of innovations and benefits to local farmers. New feeding tools are designed in a way to allow the farmer to feed all the chickens in the shed at one time while collecting chicken eggs. The introduction of of these tools saves time and energy. It also reduces the risk of food spill or food splatter. The shed is also equipped with a drip mechanism so water only comes out if pecked by the chicken. This model ensures the provision of drinking water for the chicken and is more efficient in reducing pressure on the environment. It also allows cleaner water for the chicken consumption, as opposed to the traditional chicken shed that provides open drinking water that easily gets dirty. The new shed design also maintains fresh air circulation. Better air circulation also triggers optimal egg production and ensures better chicken health as it helps improve stress management of the chickens.

PT Cargill Indonesia, which is one of the major suppliers of livestock feed products, agreed to collaborate in strengthening the resilience of chicken farmers to weather and climate change impacts. They funded and led the construction of the climate-smart chicken shed for 2,000 chickens in Ngrejo Village, Blitar District. Meanwhile, the National Smallholders Layer Farming Group provided land for the chicken shed and built a poultry learning center for smallholder chicken farmers. In the learning center, the National Smallholders Layer Farming Group or other institutions can organize capacity building activities for chicken farmers. Capacity building activities include training in good chicken farming practices, sharing experience about how climate change can affect production, and solutions to reduce risk.

The value chain of the chicken feed industry consists of input, processing, packaging, marketing, and distribution to consumer. From a business perspective, this goes beyond a Corporate Social Responsibility (CSR) program for Cargill Indonesia: by implementing the new chicken shed, this intervention becomes part of their business operation. For example, they can collaborate with the National Smallholders Layer Farming Group in Blitar to test their products. Through an increased production of eggs, their market will increase as well as their brand awareness. The new climate-smart layer chicken shed will help ensure a steady demand for chicken feed and steady supply of eggs for the country.

Investment and Outcomes

“Based on an assessment we carried out together with APIK and the National Smallholders Layer Farming Group, the chicken sheds were constructed considering surrounding conditions, with materials accessible in this region. To support this, the learning center was developed in the same area to make it easier for farmers to improve their knowledge and skills,” – Agung Baskoro, Corporate Responsibility Manager of Cargill Indonesia.

The introduction of climate-smart chicken sheds in Ngrejo Village shows real business and community adaptation action to climate impacts. The innovation will help secure better livelihoods for at least 1,000 smallholder chicken farmers. Rofi Yasifun, the leader of the National Smallholders Layer Farming Group, stated that most of the farmers in his area still apply and use traditional farming methods and chicken sheds. “All this time, most farmers in Blitar managed a simple farming system and developed their own chicken shed, basically just copying what their neighbors had made. With this new pilot climate smart chicken shed, we now have a reference as to what the ideal shed is,” said Rofi.

Two months after the launch in November 2019, the egg production in the new climate smart chicken shed has increased by 7.7%. In a traditional shed, the egg production is around 52kg per 1,000 chickens. Meanwhile in the climate smart shed, it is around 56 kg per 1,000 chickens. Out of 2,000 chickens in the new shed, 90% of them are already producing eggs. Rofi added that “the mortality rate will also be reduced due to the temperature of the shed, more comfortable for the chickens. In addition, the egg shells are cleaner as the new shed is more hygienic and the employees are more comfortable in their work.”

Other National Smallholders Layer Farming Group members in Blitar and also from neighboring districts such as Trenggalek, Tulungagung, and Lamongan have visited the climate-smart chicken shed with many of them interested to learn about the construction and building design. From that visit, around 30 smallholders chicken farmers said they were planning to replicate the design for their new chicken shed.

[1] National egg production from layer chickens is up to 1.37 million tons (Indonesia Central Bureau of Statistics – BPS, 2018), with a contribution from the East Java Province of 28.41%. Blitar District itself contributes to 70% of East Java total production.

[2] Blitar District in Numbers 2018 – BPS Kabupaten Blitar

Related resources

- Climate Vulnerability and Risk Assessment in East Java Province | Kajian Kerentanan dan Risiko Iklim Provinsi Jawa Timur

- Equipping Farmers with Climate and Weather Knowledge for More Resilient Agriculture

- CGIAR Working paper: Climate Change Impacts on Livestock

- Climate-Smart Agriculture Sourcebook and Platform

- Agriculture & Rural Development Sectors Climate Change Adaptation Guidance Note

- INSIDE STORY: Climate-smart agriculture: learning from three agro-ecological regions of Nepal

- Developing climate-smart agriculture in Nepal

- Framing innovations for climate resilience for farmers in the Sahel

- Climate-Resilient Agriculture in South Asia: An analytical framework and insights from practice

(0) Comments

There is no content